Why is Polyester Film Sand Paper good for polishing paint?

Jun 06, 2025

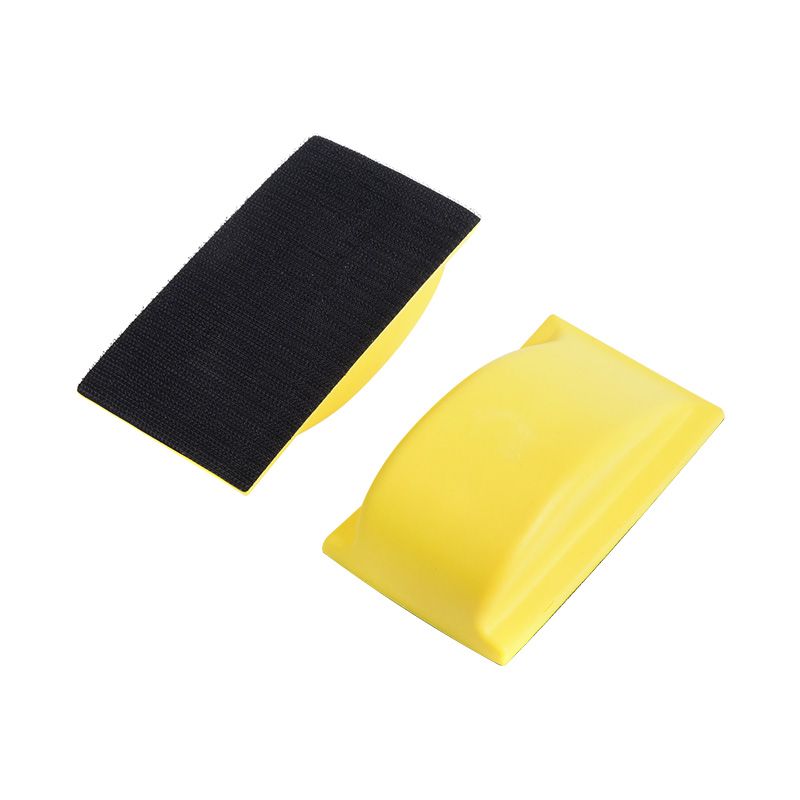

The substrate of Polyester Film Sand Paper has high tensile strength and water resistance, which is not easy to deform or tear during the sanding process, ensuring smooth and uniform operation. It is moderately flexible and can fit curved workpieces (such as car bodies or curved plastic parts) to avoid scratches or uneven sanding caused by too hard substrate. This feature makes it particularly suitable for polishing operations that require fine processing, especially surfaces with complex shapes.

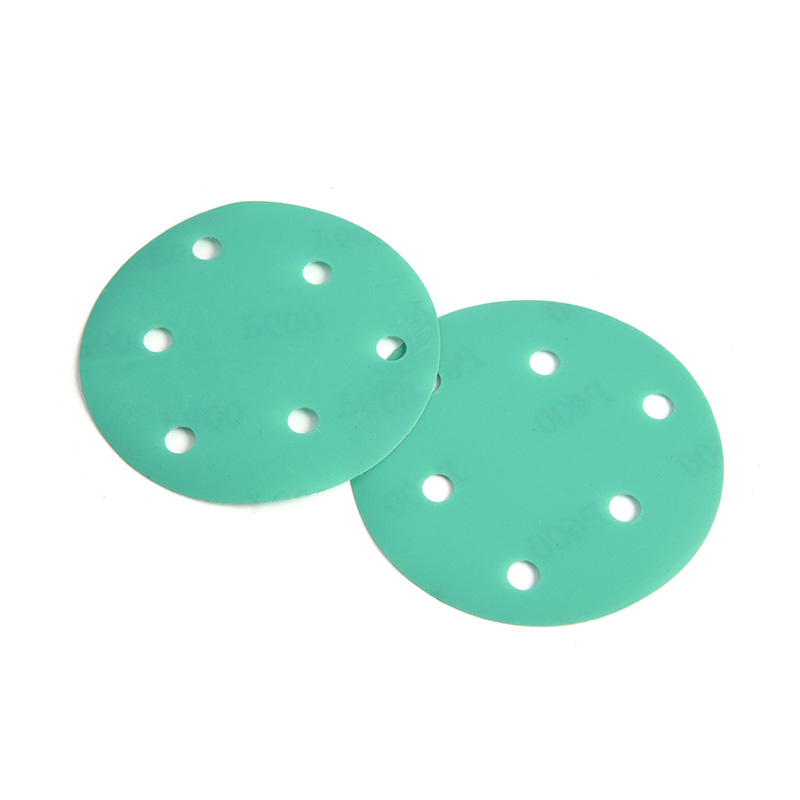

Polyester Film Sand Paper usually uses high-quality silicon carbide or aluminum oxide abrasives. These grits are sharp and wear-resistant, which can efficiently cut the paint surface without being easily dulled, extending the service life. In addition, the grit is evenly distributed through the electrostatic sanding process to avoid local excessive wear, ensure smooth and delicate paint surface after polishing, and reduce the workload of subsequent polishing.

The smooth and hydrophobic surface of the polyester film substrate can reduce the adhesion of paint powder and debris, effectively preventing the sandpaper from clogging. Under wet sanding or water washing conditions, the residue is more easily washed away, maintaining the continuous cutting ability of the sandpaper. This feature is particularly important when polishing high-viscosity paint or long-term operations, which can significantly improve work efficiency.

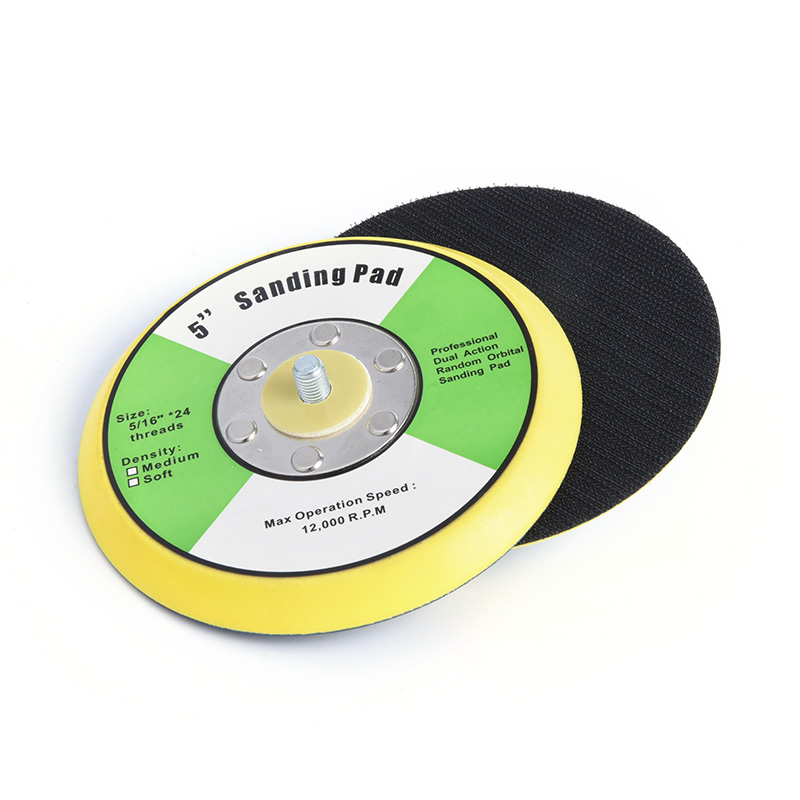

Polyester Film Sand Paper is suitable for both dry and wet sanding, and can adapt to different working environments. When dry sanding, its high temperature resistance can prevent the substrate from softening or sand grains from falling off due to friction overheating. When wet sanding, using it with water or polishing liquid can not only reduce the surface temperature and avoid the paint surface from burning, but also improve the final finish and make the polishing effect more uniform.

Polyester Film Sand Paper is available in a variety of specifications from coarse to ultra-fine, which can cover different stages of paint polishing. Coarse-grain sandpaper is suitable for removing obvious defects such as orange peel and flow marks; medium-fine grain is used to refine scratches in preparation for subsequent polishing; and ultra-fine grain can achieve a near-mirror effect and reduce the burden of the polishing process.

Some Polyester Film Sand Papers are backed with sponge to further enhance flexibility, making them better adapted to curved surfaces and edge grinding. This design prevents the problem of primer exposure caused by overcutting, and is particularly suitable for automotive repair and fine polishing of complex workpieces.

English

English 中文简体

中文简体