What specific grinding and polishing jobs are Pneumatic Sanding Pad suitable for?

Jun 13, 2025

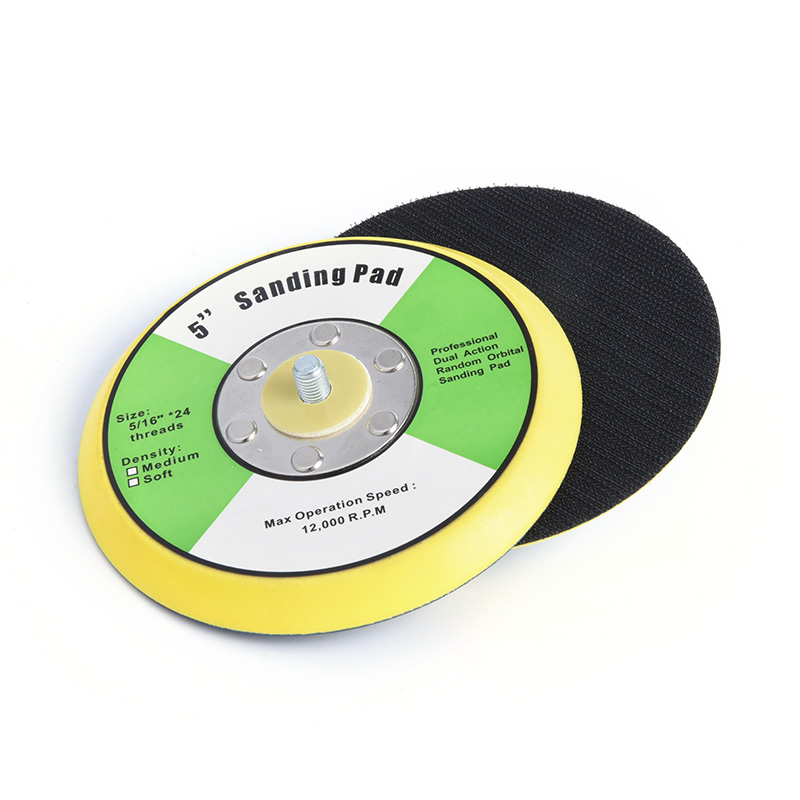

Pneumatic Sanding Pad are a type of sanding tool attachment driven by compressed air, mainly used for surface grinding, polishing and processing. It is usually installed on pneumatic tools (such as pneumatic sanders or pneumatic polishers) to grind and flatten the surfaces of various materials through high-speed rotation or vibration.

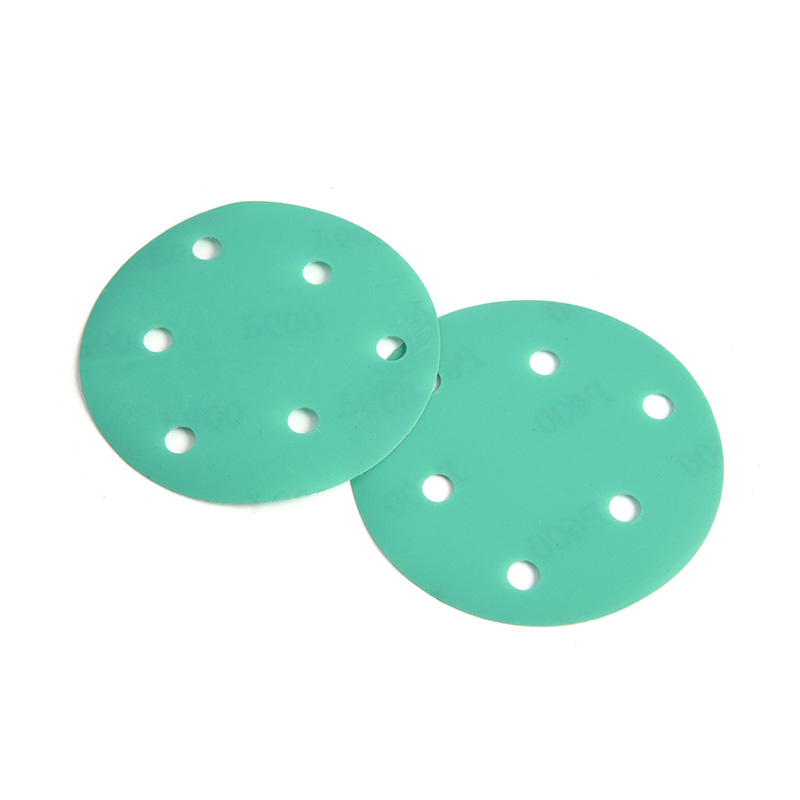

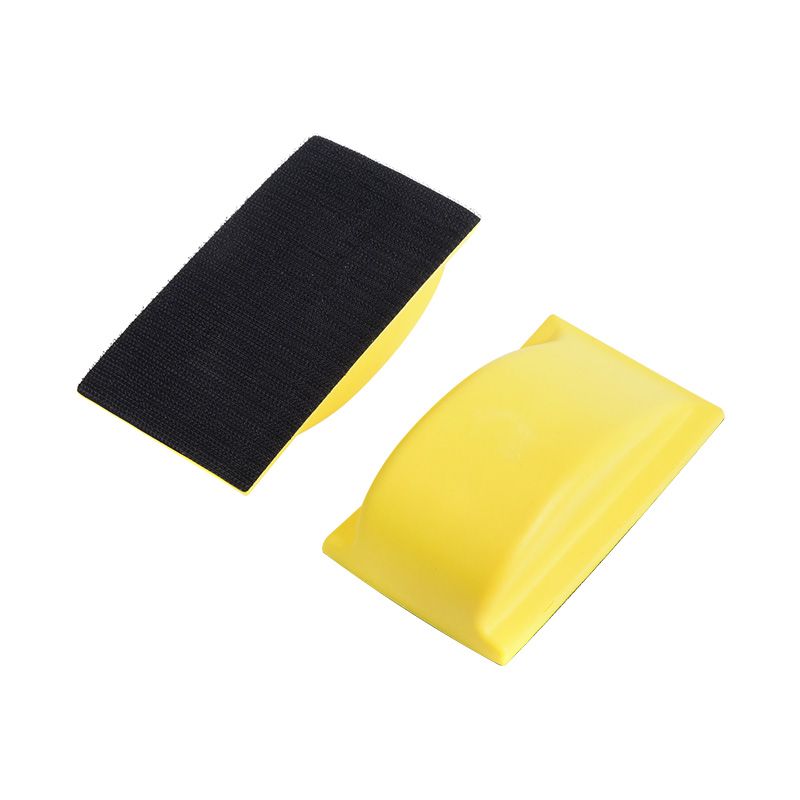

The structure of Pneumatic Sanding Pad generally includes a base plate with hooks or sticky hairs, which can easily stick sandpaper, polishing pads and other sanding materials of different types and coarseness. Its design focuses on strong viscosity and uniform distribution, ensuring that sandpaper or polishing materials are not easy to fall off during high-speed operation, improving work efficiency and safety.

Since Pneumatic Sanding Pad are pneumatically driven, the power is strong and stable during operation, which is suitable for car body waxing, scratch repair in car maintenance, surface treatment in furniture manufacturing, detail modification of embroidery crafts, and fine grinding and polishing of various materials such as metals and plastics.

Car waxing and polishing

Pneumatic Sanding Pad can be used for waxing, polishing and removing fine scratches on car surfaces. Its efficient rotation speed and uniform pressure distribution can help restore the gloss and flatness of the car paint, while reducing the unevenness of manual operation and improving the overall aesthetics of the car paint.

Furniture decoration and restoration

In the process of furniture manufacturing and restoration, Pneumatic Sanding Pad can be used to finely polish the surface of wooden furniture, remove surface burrs, old paint and stains, and lay a good foundation for subsequent painting or spraying. In addition, the polishing function can make the furniture surface smoother and improve the texture and appearance.

Embroidery and textile processing

In the post-processing process of embroidery products, Pneumatic Sanding Pad can help remove the hair and impurities on the cloth, making the embroidery pattern clearer and smoother, thereby improving the overall quality and visual effect of the finished product.

Metal surface treatment

Pneumatic Sanding Pad are also suitable for surface treatment of metal parts. They can effectively remove oxide layers, rust and fine scratches, improve the flatness of metal surfaces, and prepare for spraying or electroplating processes.

Other industrial polishing needs

In addition to the above applications, pneumatic grinding pads are also suitable for grinding and polishing of materials such as plastics and stones. Its diverse specifications and good viscosity enable it to meet the surface treatment needs of different materials and complex shapes.

English

English 中文简体

中文简体