How can Pneumatic Sanding Pad improve work efficiency when waxing a car?

Jun 20, 2025

1. Fast and uniform wax layer application

High-speed rotation/vibration: Pneumatic Sanding Pad are driven by compressed air, with high speed and stable operation. They can quickly and evenly apply car wax to the paint surface, avoiding uneven application or omissions that may occur during manual waxing.

Effort-saving and efficient: Compared with manual waxing (which requires repeated and forceful wiping), Pneumatic Sanding Pad only need to press and move lightly to complete the coverage, greatly reducing physical exertion and time costs.

2. Intelligent polishing to improve glossiness

Automatic polishing function: Some Pneumatic Sanding Pad are equipped with adjustable speed, which can perform preliminary polishing while applying wax, so that the wax layer can penetrate the paint surface more evenly and reduce the steps of subsequent manual polishing.

Reduce glare lines: The stable operation of Pneumatic Sanding Pad can avoid circular scratches (glare lines) caused by uneven force during manual waxing, and improve the final gloss effect.

3. Adapt to professional consumables and optimize the process

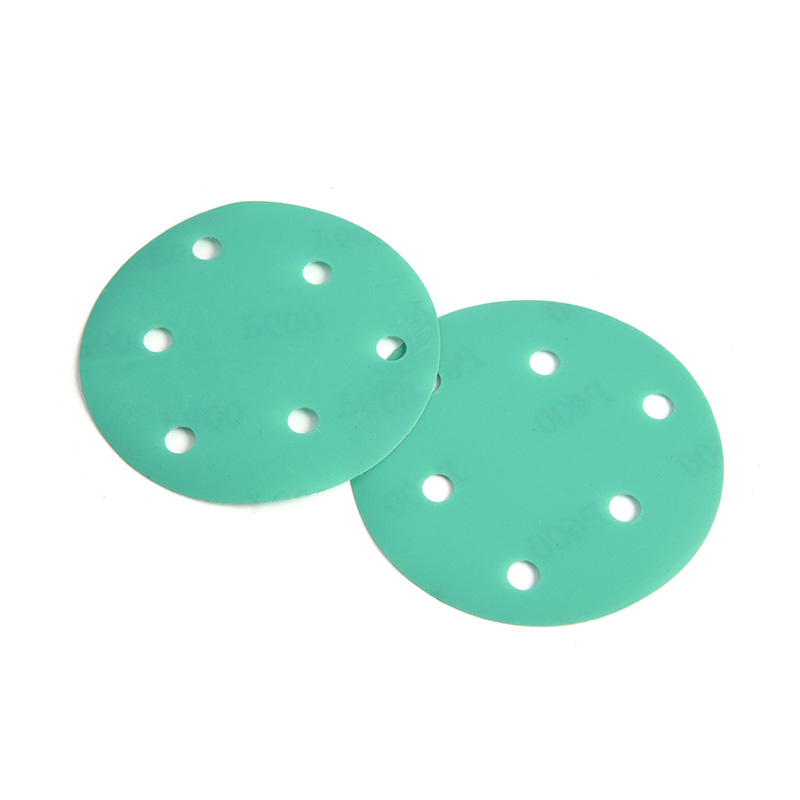

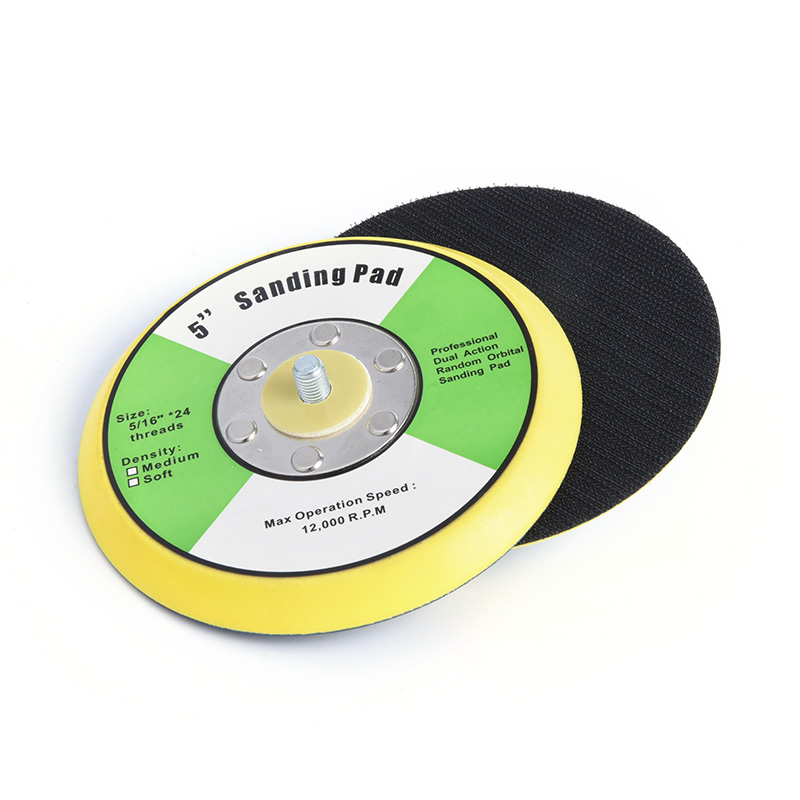

Special waxing sponge/polishing disc: Pneumatic polishing pads can be matched with high-density sponges or fiber polishing discs. These consumables have strong wax absorption and uniform wax release, which is more efficient than ordinary sponges used manually.

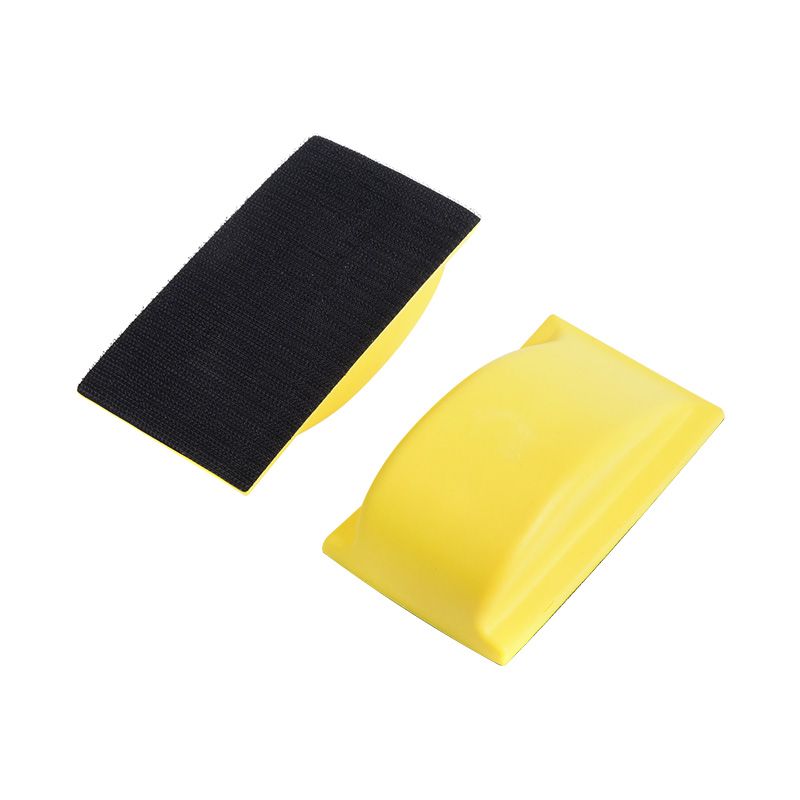

Quick replacement design: Through Velcro or quick-release structure, polishing discs of different hardness can be quickly switched to adapt to multiple processes such as waxing and polishing, reducing tool replacement time.

4. Suitable for large-area operations

Faster body coverage: For large vehicles such as SUVs and MPVs, manual waxing takes a long time, while pneumatic polishing pads can quickly handle large flat areas such as roofs and hoods, increasing efficiency by more than 50%.

Flexible corner processing: With small or special-shaped polishing heads, complex parts such as grilles and rearview mirrors can also be efficiently processed to avoid the dead angle problem of manual operation.

5. Reduce rework rate

Avoid excessive wax layer or residual wax: The uniform pressure of the pneumatic sanding pad can prevent wax accumulation ("wax stains" are prone to occur during manual work), reducing the need for manual correction with towels in the later stage.

English

English 中文简体

中文简体