How does the overall structural design of the Soft Edge Electric Sanding Pad consider the balance between ease of operation and sanding effect?

May 30, 2025

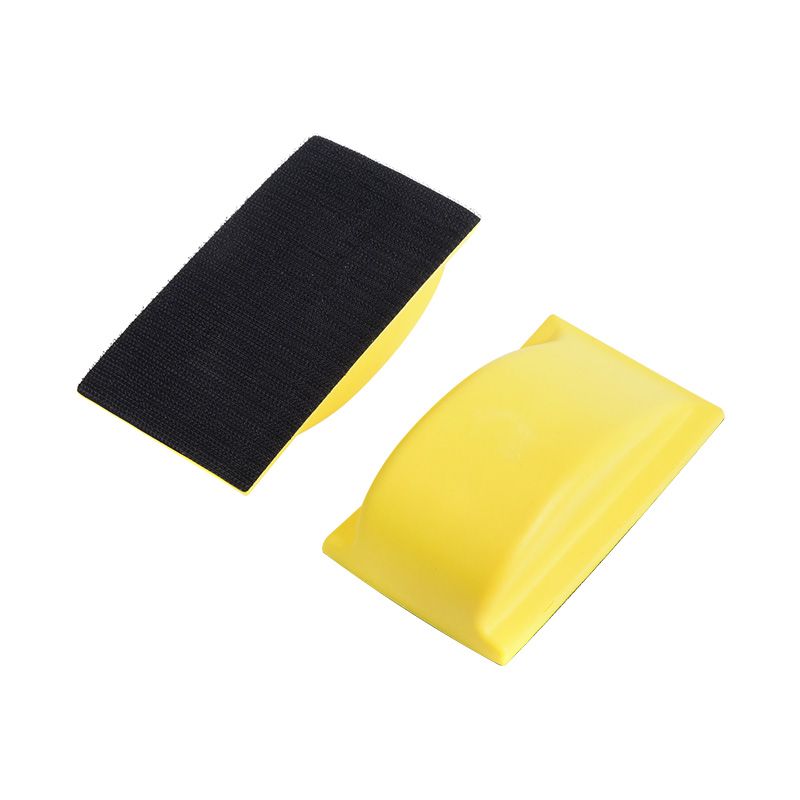

The soft edge of the Soft Edge Electric Sanding Pad is made of soft and elastic materials. This design allows the sanding pad to better fit surfaces of different shapes and curvatures such as cars and glass during operation. During the sanding process, the soft edge can automatically adapt to the ups and downs of the surface, reducing the trouble of frequently adjusting the angle and pressure due to uneven surfaces during operation, and improving the convenience of operation. At the same time, the elasticity of the soft edge can also buffer the pressure during sanding to a certain extent, avoid excessive damage to the surface, and ensure the uniformity of the sanding effect.

The middle sanding area of the sanding pad usually uses a material with moderate hardness and good wear resistance to ensure that the surface defects and unevenness can be effectively removed during the sanding process to achieve a good sanding effect. The reasonable combination of the soft edge and the middle sanding area not only ensures the working efficiency of the sanding area, but also makes the entire sanding pad more flexible during operation through the buffering effect of the soft edge, and is not easy to cause scratches and other damage to the surface due to excessive force or improper operation.

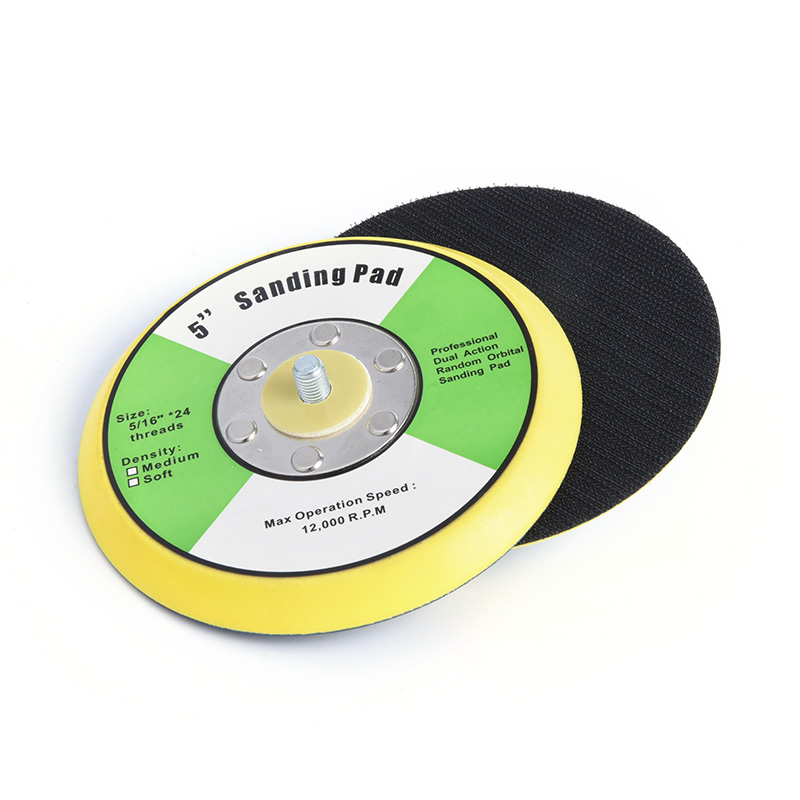

Soft-edged electric sanding pads are usually designed with easy-to-use mounting interfaces, which can be quickly and easily installed on electric sanding equipment. This design reduces the time and energy consumption during the installation process and improves the convenience of operation. At the same time, the stability of the mounting interface also ensures that the sanding pad will not loosen or fall off during the sanding process, thereby ensuring the stability of the sanding effect.

Reasonable weight and size design are also key factors in balancing the convenience of operation and the sanding effect. The sanding pad should not be too heavy, otherwise it will increase the labor intensity of the operator and reduce the convenience of operation; but it should not be too light, otherwise it may not provide enough sanding pressure and affect the sanding effect. In addition, the size design also needs to take into account the flexibility of operation, which should be able to cover enough sanding area and be easy to operate in a small space.

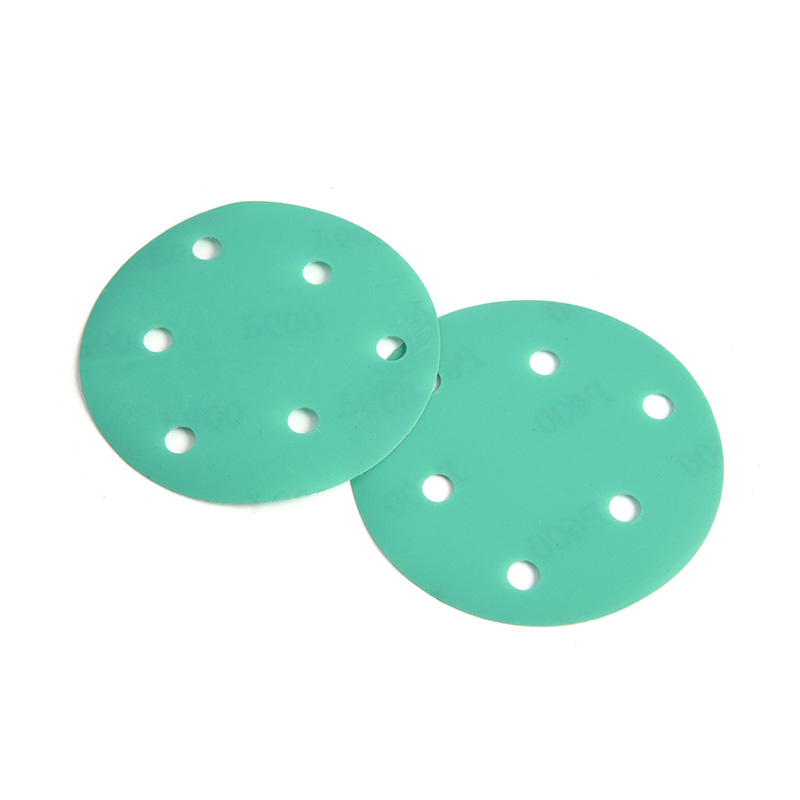

During the sanding process, the friction between the sanding pad and the surface will generate heat. If the heat cannot be dissipated in time, it may cause the sanding pad to deform or damage, and also affect the sanding effect. Therefore, some soft-edged electric sanding pads are designed with heat dissipation holes or heat dissipation channels to speed up the heat dissipation and ensure that the sanding pad can maintain stable performance during long-term use, thereby improving the convenience of operation and the sanding effect.

A large amount of dust will be generated during the sanding process, which will not only affect the health of the operator, but may also enter the sanding pad, affecting its performance and service life. Therefore, some sanding pads will adopt dust-proof designs, such as setting up dust covers or sealing structures to reduce the entry of dust, ensure the normal operation of the sanding pad, and also improve the convenience and safety of operation.

English

English 中文简体

中文简体