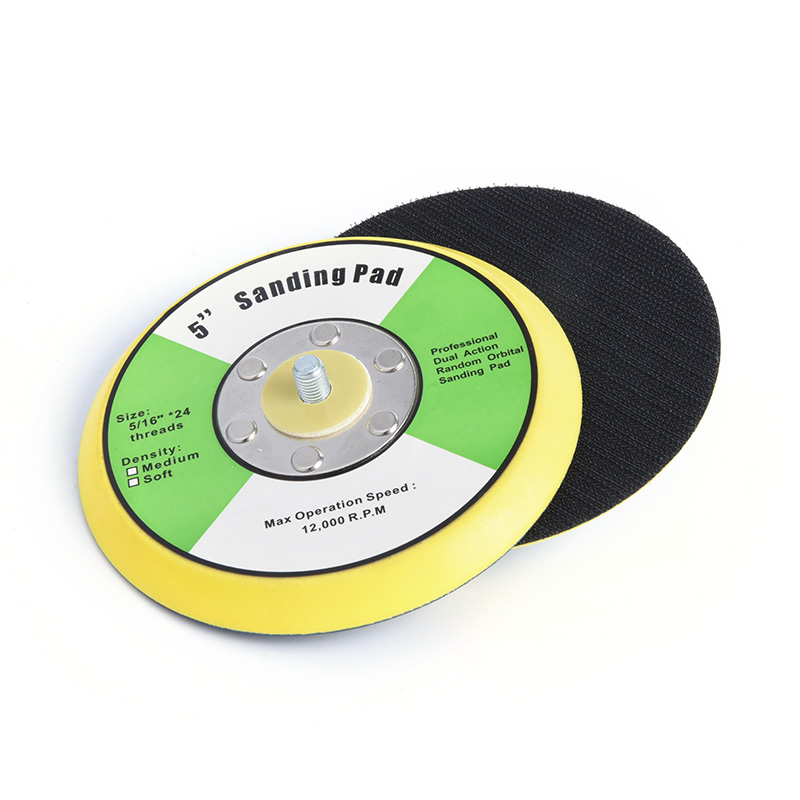

How does the torque performance of the 6 inch G15 49holes Electric Backing Pad perform at different speeds?

May 23, 2025

Torque performance is an important indicator to measure the output rotational force of the 6 inch G15 49holes Electric Backing Pad at different speeds. It is not determined by a single factor, but is affected by a combination of multiple complex factors. For the 6 inch G15 49holes Electric Backing Pad, its torque performance is also restricted by many factors such as motor design, transmission structure and load characteristics.

The motor is the power source of the electric backplane, and its performance directly determines the output capacity of the torque. There are differences in the design of motors of different brands and models. For example, the winding method, number of magnetic poles, power size, etc. of the motor will affect the torque. Generally speaking, a motor with a higher power may output a greater torque at the same speed. However, knowing only the motor power parameter is not enough to accurately determine the torque, because the torque output characteristics of the motor at different speeds are not linear. Some motors can output a larger torque at low speeds, which is suitable for occasions requiring high starting torque; while some motors have relatively stable torque output at high speeds, which is more suitable for high-speed applications. Therefore, without specific product technical parameters, it is difficult to know exactly the torque characteristics of the motor used in the 6 inch G15 49holes Electric Backing Pad.

The transmission structure of the electric backplane is responsible for transmitting the power generated by the motor to the backplane to rotate it. Common transmission structures include gear transmission, belt transmission, etc. Gear transmission has the advantages of high transmission efficiency and accurate transmission ratio, but there may be certain friction losses during the transmission process, which affects the transmission of torque. Gears of different materials, precision and lubrication conditions have different friction losses, which leads to differences in the torque finally transmitted to the backplane. Belt transmission has the characteristics of simple structure, buffering and shock absorption, but the belt will elastically slide during the transmission process, which will also cause certain power loss and reduce the transmission efficiency of torque. Therefore, the design and manufacturing quality of the transmission structure will have an important impact on the torque performance of the electric backplane.

Load characteristics refer to the various external forces that the electric backplane is subjected to during work, such as polishing pressure, friction, etc. In the polishing operation, the magnitude of the polishing pressure will directly affect the load borne by the backplane. When the polishing pressure increases, the backplane needs to overcome greater resistance to keep rotating, which requires the motor to output greater torque. At the same time, the friction between the polishing object and the back plate of different materials is also different. The greater the friction, the greater the torque required for the back plate to rotate. In addition, the change in load will also affect the speed-torque characteristics of the motor, making the torque performance of the electric back plate under different working conditions more complicated.

English

English 中文简体

中文简体