What are the advantages of soft-edged electric sanding pads over traditional tools in fine polishing tasks?

Jul 11, 2025

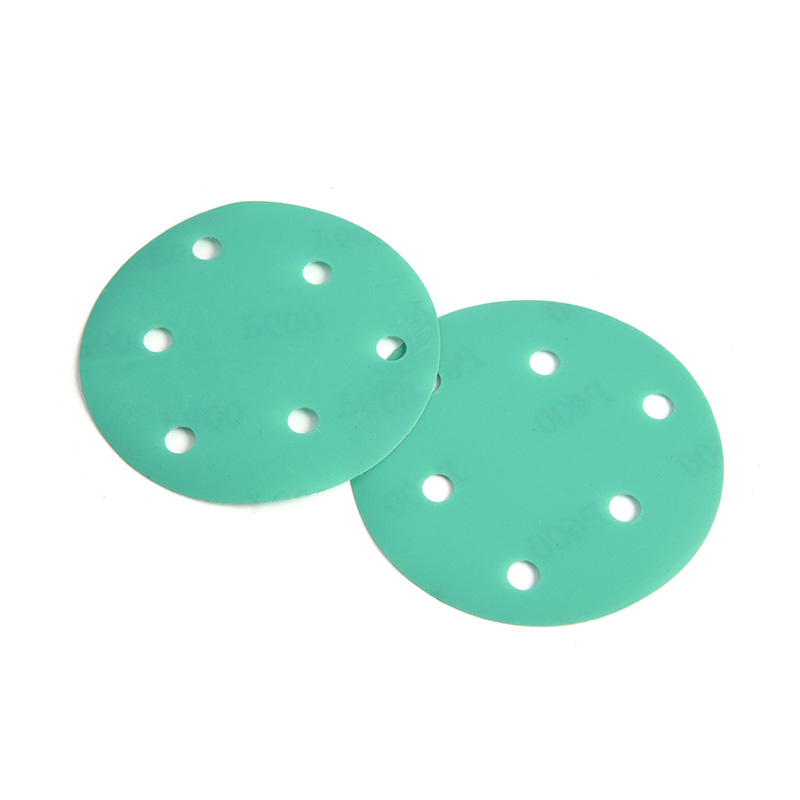

In fine polishing tasks, the soft-edged electric sanding pads are designed with flexible materials (such as sponges, elastic rubber or microfiber), which can fit tightly to complex surfaces (such as car curved surfaces, jewelry grooves), avoiding uneven polishing or omissions caused by traditional hard sanding pads due to excessive rigidity.

Traditional hard sanding tools (such as sandpaper, metal polishing wheels) are prone to leaving scratches due to uneven pressure or operating errors, while the elastic buffer of soft-edged pads can automatically adjust the contact pressure and reduce the risk of damage.

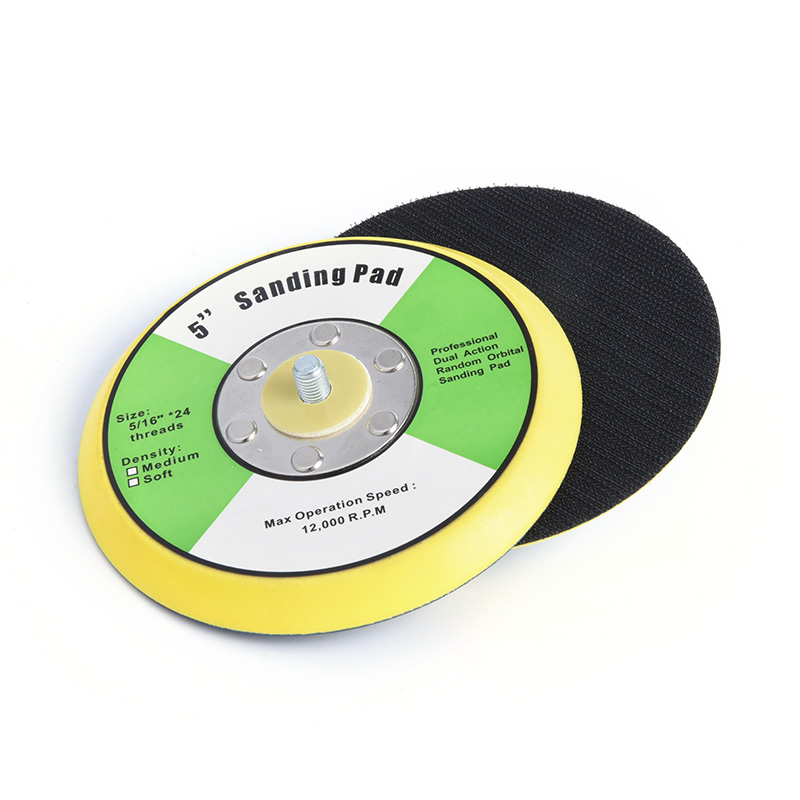

Compared with manual polishing (such as using cloth wheels or polishing paste), electric sanding pads can quickly complete polishing through high-speed rotation or vibration, and the efficiency is increased several times, which is especially suitable for large-scale operations (such as car beauty shops). Most soft-edged sanding pads use Velcro or snap-on designs, and it only takes a few seconds to replace the polishing pad, while traditional tools may require the removal of screws or re-fixing of sandpaper.

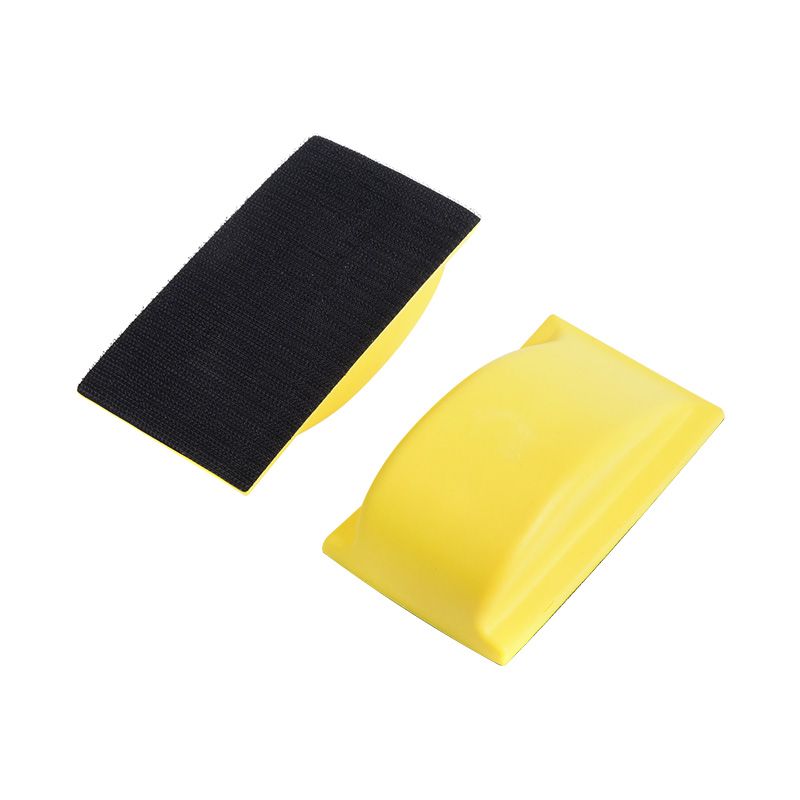

It can easily handle details that are difficult to reach with traditional tools (such as around car logos and jewelry hollow patterns), while hard grinding pads are only suitable for flat surfaces. By replacing polishing pads with different hardness or grain size, the same device can complete both rough grinding (such as removing oxide layers) and mirror polishing (such as chrome-plated parts or gemstones), while traditional tools usually require multiple process switching.

The shock absorption characteristics of soft-edged materials can reduce the common jitter problems of power tools and avoid accidental slippage and damage to workpieces during polishing. Traditional metal polishing wheels are prone to overheating and burning surfaces (such as car paint or silver ornaments) due to high-speed friction, while the heat dissipation design of soft-edged pads is more gentle and suitable for temperature-sensitive materials.

Soft-edged pads wear evenly and are replaced less frequently than sandpaper or hard grinding heads that are prone to cracking. Traditional manual polishing requires repeated application of polishing paste, while the rotational force of electric soft pads can evenly distribute the polishing agent and save more.

Traditional hard wheels may cause "sun patterns" on the paint surface due to excessive edge pressure, while soft-edged pads can repair scratches without marks. Polishing silver jewelry by hand with an agate pen takes hours, but an electric pad can complete the task in minutes and with a more even brightness.

English

English 中文简体

中文简体