Are Hand Sanding Bloock really more efficient than ordinary sandpaper?

Jul 04, 2025

In modern industry and hand-made production, Hand Sanding Bloock, as an important sanding tool, have been widely welcomed because of their lightness, efficiency and comfort. Hand Sanding Bloock are not only suitable for car surface polishing and jewelry care, but also widely used in woodworking, furniture, metal, stone and other fields.

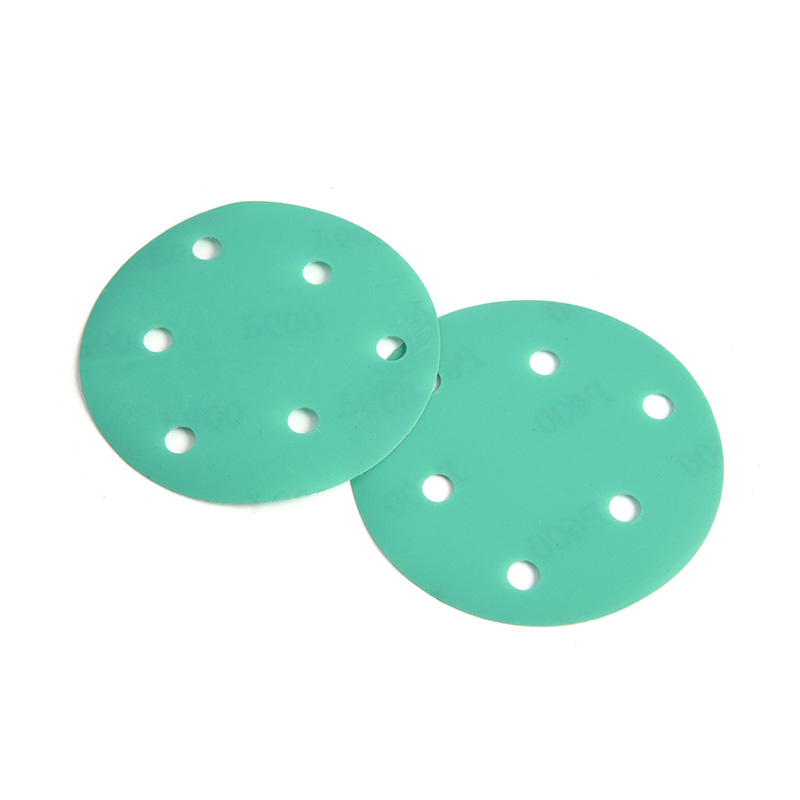

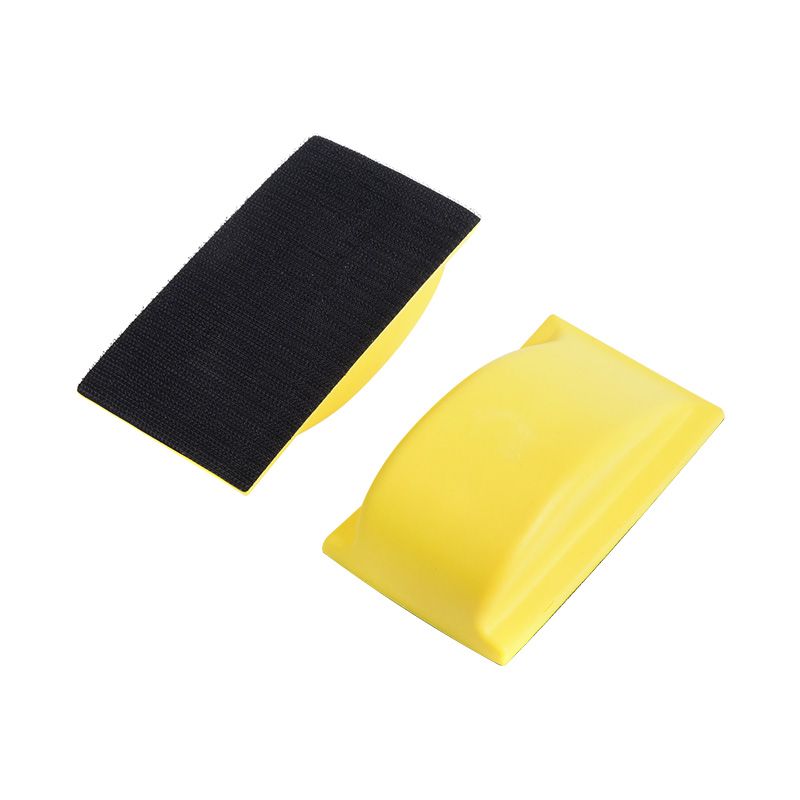

Hand Sanding Bloock are a tool used for manual sanding and polishing, usually made of polyurethane, nylon foam, sponge, diamond sand and other materials. These materials have good flexibility and wear resistance, which can effectively reduce hand fatigue and improve work efficiency. Hand Sanding Bloock are compact in design, light in weight, comfortable to hold and easy to use, suitable for sanding and polishing tasks of various materials.

1. Ergonomic design to improve comfort and efficiency

In the design of modern hand-made sanding tools, ergonomics has become an important factor in improving user experience. Many Hand Sanding Bloock adopt mouse-shaped or arc-shaped designs, which can fit the palm perfectly, allowing users to maintain a good grip and control during long-term use. This design not only reduces hand fatigue, but also improves the accuracy and efficiency of grinding.

2. Multi-purpose applicability to meet the needs of a variety of materials and scenarios

Another major advantage of manual sanding blocks is their wide applicability. They are not only suitable for common materials such as wood, metal, stone, glass, and ceramics, but also play an important role in many fields such as car beauty, jewelry care, furniture making, and tile trimming.

Wood and furniture: It can be used for rough grinding, fine grinding, and polishing of wood surfaces to help create a smooth and delicate wooden surface.

Metal processing: It is suitable for metal rust removal, wire drawing, polishing and other processes to enhance the gloss and texture of metal surfaces.

Jewelry and cultural relics: In fine operations such as jewelry polishing, bracelet making, and cultural relics polishing, manual sanding blocks can provide precise control to ensure that each work reaches the ideal state.

Car beauty: In the processes of grinding putty and polishing after car painting, manual sanding blocks can effectively remove sandpaper marks and make the car paint surface smoother and brighter.

Tiles and stones: can be used to trim the edges of tiles and polish the surface of stones to improve the overall aesthetics.

3. Adjustable and replaceable, flexible to meet different task requirements

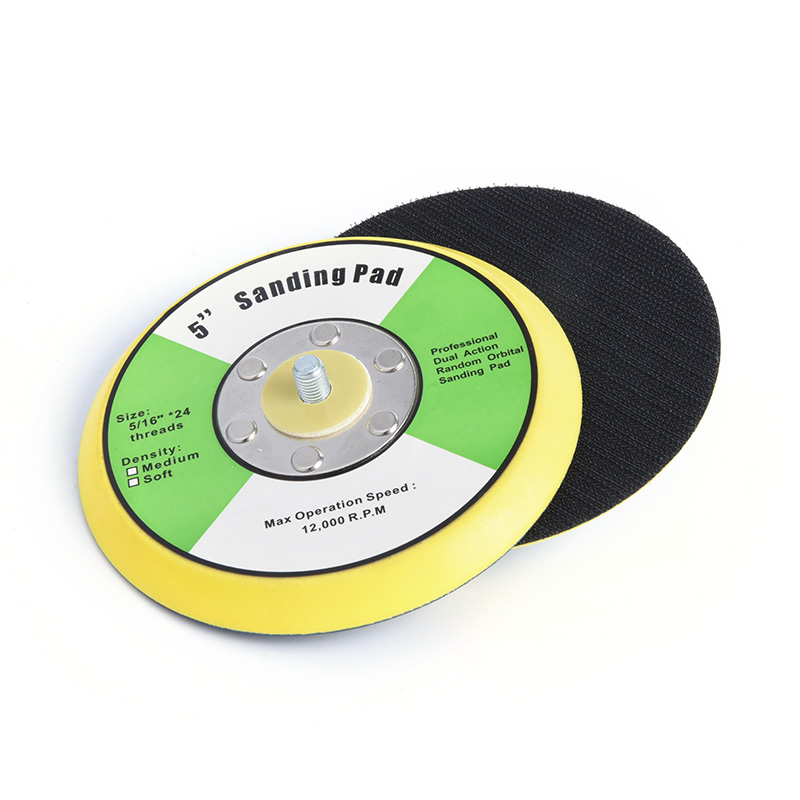

In order to meet the needs of different grinding tasks, some high-end manual sanding blocks are equipped with replaceable sandpaper or abrasive systems. Users can choose abrasives of different meshes according to specific tasks, so as to achieve seamless switching from coarse grinding to fine grinding. For example, low-mesh abrasives are suitable for removing burrs and rough grinding surfaces, while high-mesh abrasives are suitable for fine grinding and polishing.

This adjustable design not only improves the flexibility of the product, but also extends the service life of the sanding block and avoids waste caused by a single task. For users who need to frequently change grinding tasks, this design is undoubtedly a very practical plus.

4. High durability to ensure long-term stability

In terms of manufacturing technology, manual sanding blocks usually use high-density materials and advanced manufacturing processes to ensure that they are not easy to wear or deform during long-term use. For example, polyurethane sanding blocks have good flexibility and wear resistance, can maintain a stable shape during repeated use, and are not easy to crack or break.

In addition, some products also use tear resistance and anti-aging technologies, so that they can still maintain good performance in harsh environments such as humidity and high temperature. This high durability not only extends the service life of the product, but also reduces the user's replacement frequency and use cost, which is an ideal choice for users who pursue cost-effectiveness.

In which industries are manual sanding blocks most popular?

1. Car beauty

In the field of car beauty, manual sanding blocks are an important tool for improving the appearance quality of vehicles. They are often used for body sanding, post-painting putty grinding, and final polishing. By using sanding blocks with different mesh counts, the old paint layer can be gradually removed, body defects can be filled, and the paint surface can be made smoother and more uniform. For example, low-mesh sanding blocks are used for coarse grinding, while high-mesh sanding blocks are used for fine polishing to achieve a mirror effect.

2. Woodworking and furniture

In woodworking and furniture manufacturing, hand sanding blocks are used for wood surface grinding, furniture surface treatment, and polishing after carving. They can effectively remove burrs and unevenness on the wood surface, making the wood surface smoother and more delicate. In addition, hand sanding blocks can also be used for furniture repair and renovation, helping to remove scratches and old paint, and restore the beauty and functionality of furniture.

3. Metalworking

In the field of metalworking, hand sanding blocks are used in processes such as metal rust removal, wire drawing and polishing. They can remove oxide layers, rust and stains on the metal surface, making the metal surface smoother and more beautiful. For example, red corundum grinding wheel heads are widely used in jewelry cutting, trimming and polishing due to their high hardness and wear resistance. In addition, graphite sanders also perform well in metal processing and can improve the surface quality and precision of metal parts.

4. Jewelry and collectibles

In the field of jewelry and collectibles, hand sanding blocks are used for fine operations such as jewelry polishing, collectibles polishing and bracelet making. They provide precise control to ensure that every piece of work is in ideal condition. For example, red corundum grinding wheels can cut, trim and polish materials such as metals, gemstones and jade, making the surface of jewelry smoother and more shiny. In addition, felt grinding heads are also widely used in the polishing of jewelry and cultural relics, which can provide a uniform polishing effect.

5. Tiles and stones

In tile and stone processing, manual sanding blocks are used for tile trimming and stone surface treatment. They can level the surface of stone, remove bumps and flaws of stone, and make the surface of stone smooth and shiny. For example, diamond grinding blocks and sponge grinding blocks are widely used for tile trimming and stone surface polishing, which can effectively remove edge burrs and improve the flatness and beauty of stone.

Common sizes of manual sanding blocks include 6 inches × 3 inches × 2 inches, 98 × 120 × 13mm, 25 × 90mm, etc. There are various shapes, including planes, arcs, grooves, chamfers and other shapes to meet different polishing needs. Some products support hook-and-loop connection and can be used with electric sanders to improve work efficiency.

As a versatile and efficient sanding tool, hand sanding blocks not only play an important role in industrial production, but are also widely used in handmade production. Its lightness, durability and easy operation make it an ideal choice for manual sanding and polishing. Whether it is car beauty, woodworking or jewelry care, hand sanding blocks can provide excellent performance and user experience to meet the needs of different scenarios.

English

English 中文简体

中文简体