How to ensure the accuracy and safety of the sanding process when using a 2 Inch Dual Action Random Orbital Sanding Pad?

May 02, 2025

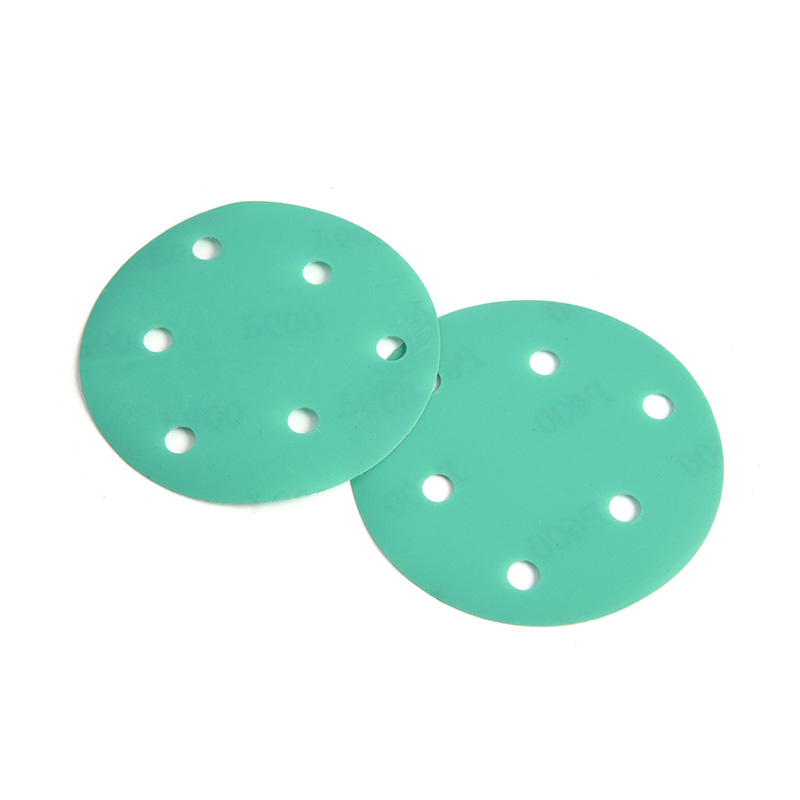

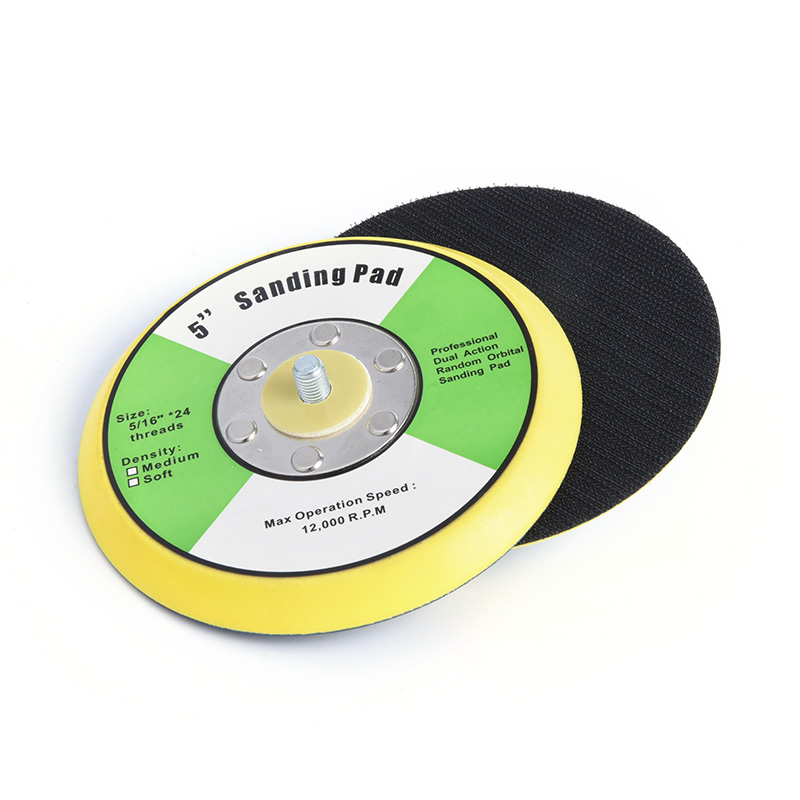

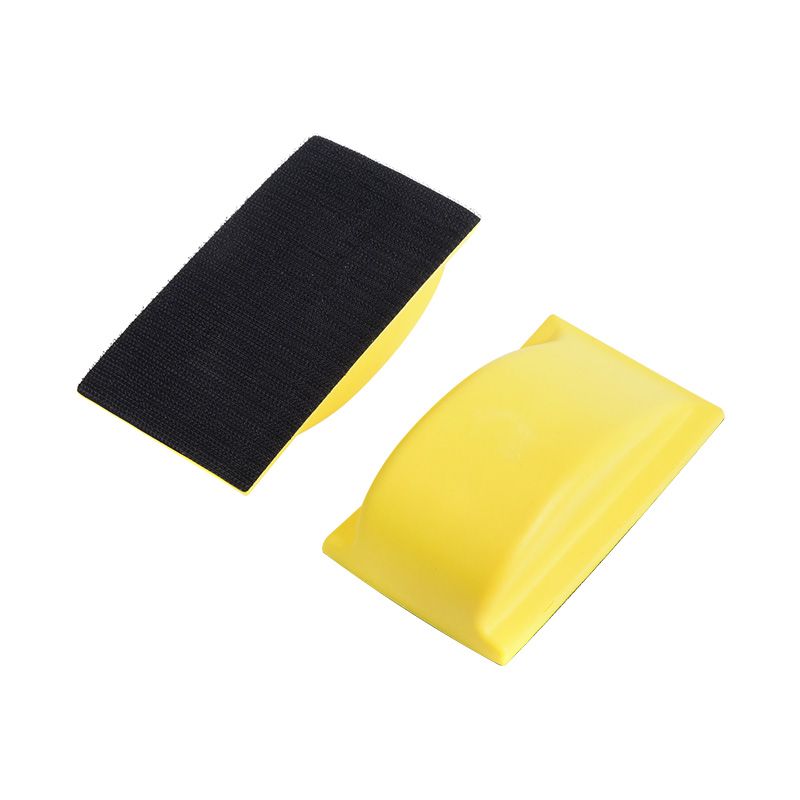

The 2 Inch Dual Action Random Orbital Sanding Pad is equipped with two threaded interfaces, M6 and 5/16-24. Users need to ensure that the sanding pad is firmly connected to the equipment during installation. An unstable threaded connection during use may cause the tool to loosen, which in turn affects the sanding accuracy and increases safety hazards during use. Make sure that the threaded connection is tightened in place to avoid loosening or falling off. The sanding pad is equipped with a sturdy hook and loop fixing design, which can effectively prevent the sanding pad from shifting and rotating during use. This not only maintains the consistency of the sanding process, but also avoids the safety risks caused by the sanding pad falling off at high speeds.

During use, do not apply excessive pressure. Excessive pressure can cause damage to the sanding pad, and it will also affect the sanding effect, causing uneven wear on the work surface and even overheating of the tool. Appropriate pressure can help achieve finer sanding while extending the life of the tool. Maintain a uniform gesture and angle when sanding, and avoid concentrating too much pressure in one place to ensure uniformity across the entire work surface.

Adjust the speed to the right one for the material and the coarseness of the sandpaper. Too high a speed may cause the sandpaper to wear out prematurely, while too low a speed may not achieve the desired grinding effect. Ensuring the right speed can improve work efficiency and ensure the accuracy of sanding. The double-action random orbit technology used in this sanding pad can effectively reduce streaks or paint scratches left during sanding. The randomness of this technology prevents sanding from having a fixed track, reducing the risk of surface damage, thereby improving the accuracy and surface quality of sanding.

When sanding, it is necessary to maintain the stability of the tool in contact with the workpiece to avoid uneven sanding due to unstable hands or unstable equipment. Keep the tool parallel to the work surface and avoid tilting or excessive tilting to reduce unnecessary surface wear and scratches. During operation, avoid fast and violent lateral or longitudinal movements, and try to move slowly and smoothly to ensure the accuracy of the sanding process.

When using sanding tools, it is recommended to wear appropriate protective equipment such as dust masks, eye protection glasses and ear plugs. The sanding process generates dust and noise, which may have adverse health effects if exposed for a long time. Wearing protective equipment can effectively reduce these risks. Before each use, check that the sanding pad and various parts of the tool are intact. In particular, make sure that the hook and loop fixing design and threaded connection parts are not loose or damaged. During use, if the tool is found to have abnormal vibration or noise, it should be stopped and inspected immediately to avoid safety problems caused by equipment failure.

English

English 中文简体

中文简体