How does the softness of this 3 Inch Polyurethane Sanding Pad help the sanding effect?

May 09, 2025

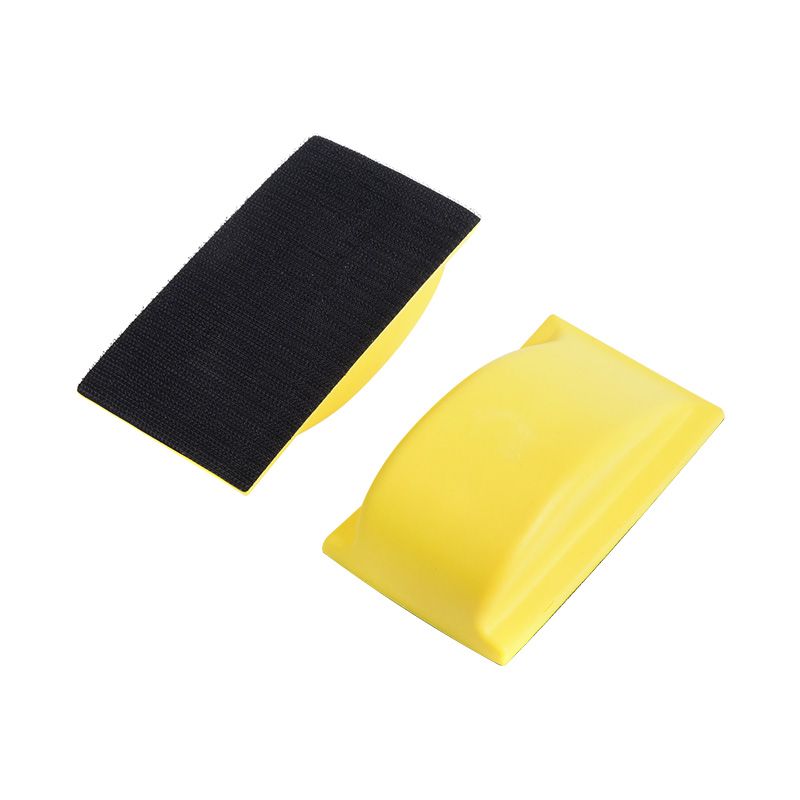

The softness of the 3 Inch Polyurethane Sanding Pad allows it to fit closely to the surface of the workpiece, achieving uniform contact even on complex curved surfaces or uneven areas. Traditional hard sanding discs are often unable to fully adapt to irregular shapes due to their strong rigidity, which can easily lead to uneven sanding or missing certain areas. The soft polyurethane foam can deform naturally with the contour of the workpiece surface to ensure that the sanding force is evenly distributed, which is particularly suitable for processing sculptures, molds, or metal, wood and plastic products with arcs.

Because the polyurethane material has good elasticity, it can buffer pressure during the sanding process and avoid scratching the surface of the material due to excessive force. This feature makes it particularly suitable for fine sanding and final polishing stages, which can effectively reduce the occurrence of deep scratches and make the surface of the workpiece smoother and more delicate. In contrast, hard sanding discs are prone to leave obvious wear marks due to rigid contact, while soft polyurethane sanding pads can provide a gentler grinding effect and are suitable for applications with high requirements for surface finish.

For soft or fragile materials, hard sanding discs may cause dents or deformation due to excessive local pressure. The softness of polyurethane sanding pads can disperse the sanding pressure and reduce the risk of material damage. Even at high speeds, its elasticity can absorb part of the impact force, reducing damage to the workpiece caused by accidental collisions or improper operation, thereby improving the safety and controllability of sanding.

Polyurethane foam has excellent resilience and fatigue resistance, and can quickly return to its original state after being compressed, avoiding permanent deformation or wear caused by long-term use. This feature allows sanding pads to maintain stable sanding performance for a long time and reduce the frequency of frequent replacement. In contrast, traditional hard sanding discs are prone to failure due to local wear, while soft polyurethane sanding pads can consume abrasives more evenly and extend the overall service life.

The soft polyurethane material can effectively absorb the vibration generated during the sanding process, reduce the impact on the hands, and thus reduce the fatigue of the operator. Especially during long-term continuous operation, this feature can significantly improve the comfort of use and make the sanding work easier and more efficient. In addition, since the flexibility of the sanding pad can adapt to different force application methods, the operator can control the sanding force more flexibly and further improve work efficiency.

English

English 中文简体

中文简体